The COPROMEC plunger tip is an innovative solution built for cold chamber high pressure die casting machines (aluminium and magnesium). The innovation consists in using the force of liquid aluminium during the injection process, in order to push the rings against the shot sleeve walls. The plunger tip body is made of special steel developed to resist to heavy working conditions in the die casting process and to strong thermal shocks (aluminium 600°C – water 30°C). The copper rings, seating in grooves realized on the plunger tip, are realized in a special pressed copper alloy. The copper rings are always in contact with the shot sleeve and they work as a seal for liquid aluminium, as in a hydraulic system. Between the plunger tip head and the first ring, there are specific holes to allow the liquid aluminium to enter under the ring. At each injection the ring enlarges thanks to the solidified aluminium built up under the ring, filling the external wear.

SUPER DIE CASTING

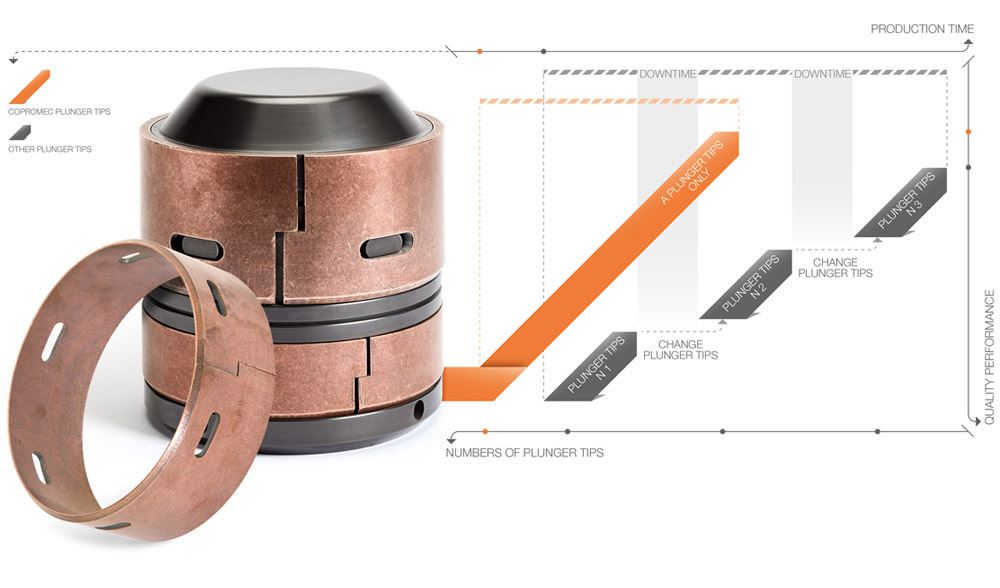

The patented Copromec plunger tip.

Advantages of the COPROMEC system:

- User-friendly system and production efficiency

- Acceptance of operator mistakes without causing irreparable damages (ring breaking at most)

- Continuous injection cycles thanks to compensation created by copper rings

- Decrease of down time machine

- Reduction of the cycle time

- Longer life time of the shot sleeve

- Compensation of shot sleeve ovalization and tapering

- Compensation of wider tolerances

- It supports and balances mistakes due to missing lubrication

- Excellent tightness of vacuum system

Besides the plunger tip.

In addition to the plunger tips, we provide all other components for the injection system of pressure casting: rods, shot sleeves, lubricants, water jackets and lubrication systems. Thanks to our products, we have realized the best technologies for the injection group, with the only aim to solve your problems. We believe that starting your requests is the best way to create a range of specific products, that change according to the machine and the die type and satisfy your real needs as for the quantity of heat to control, and that meet all the variables of your production process.

Copromec lubricated plunger tip

Our new, patented, system presents a lubricated plunger tip currently used in the production of automotive structural parts. Advantages include a better vacuum seal and a longer lifetime for the shot sleeve, rod and plunger tip. This innovation is the outcome of constant research and development to ensure high quality industrial technologies. Additional applications include use with specific alloys and many other production needs. Its performance optimizes the process time and the lifetime of eachcomponent,guaranteeing low porosity of aluminum casting, reduced lubricant quantity and improved biscuit solidification time.