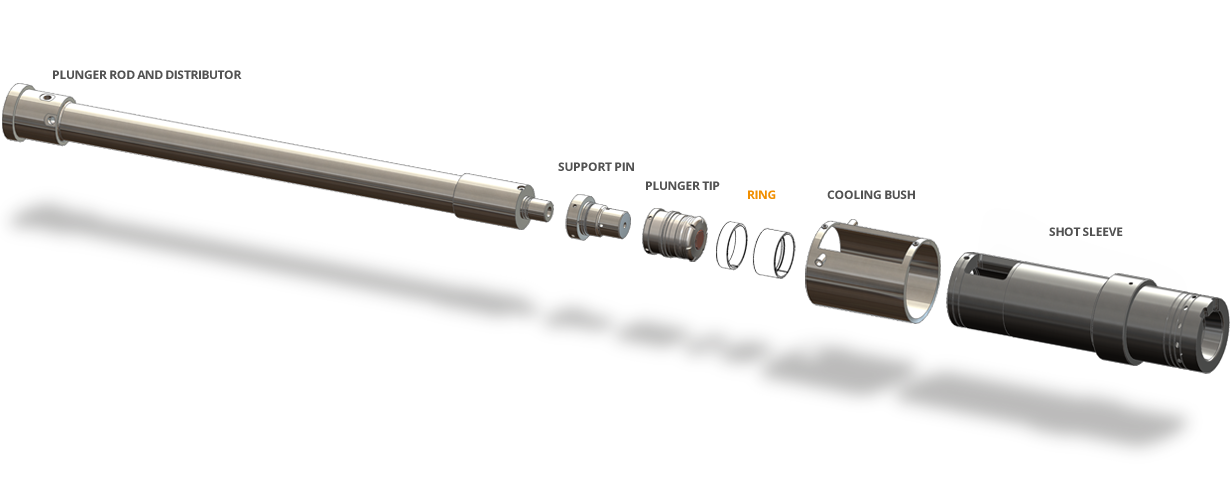

The rings are positioned in specific seats on the plunger tip and are composed of a particularly pressed copper alloy. They are always in contact with the shot sleeve perimeter and work as sealing rings for the liquid aluminium, as in a hydraulic system. Between the plunger head and the first ring there are shaped ducts to permit the flow of liquid aluminium under the ring. The rings use the ‘energy’ of molten aluminium to adhere to the shot sleeve walls, so they are regulated at each shot and the aluminium that solidifies, creating thin layers under the ring, compensates the external wear of the ring itself.

Copper Rings

COPPER RINGS